More than mopping up.

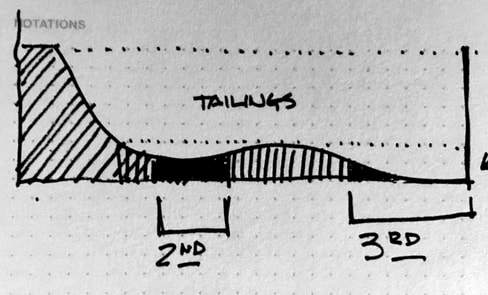

/ Back diffusion

|

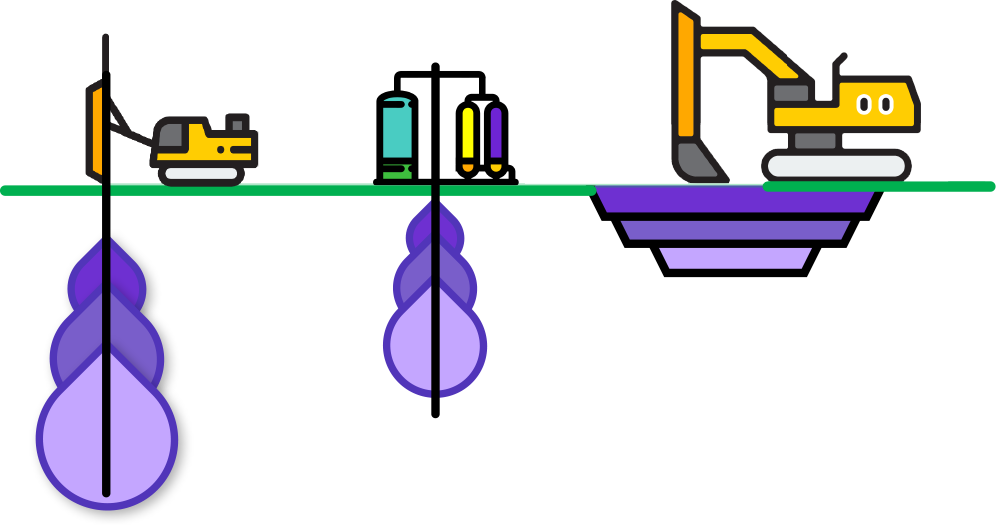

Retreatment is generally accepted as a best practice in ISCO projects. But the benefits of controlled release oxidants have been proven to yield many different positive outcomes with the wide range of different environmental and pollutant factors including:

|

Eliminating the Rebound

Over time, contaminants change physical states.

What Causes Rebounding?

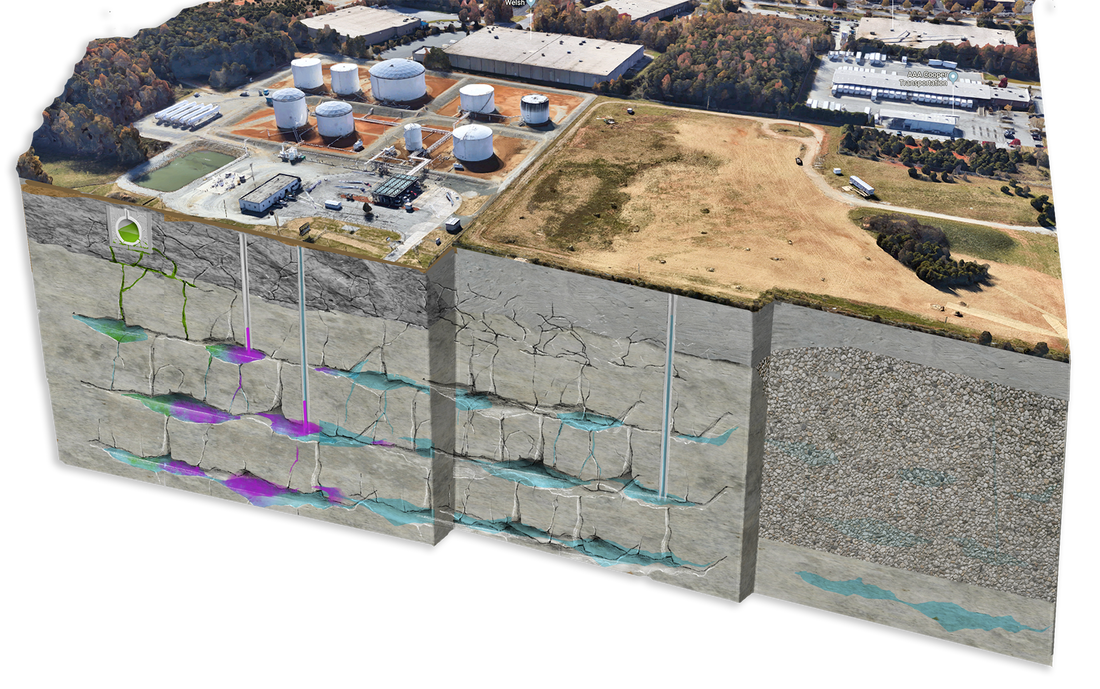

Contaminant mass can be dissolved in groundwater, sorbed onto solids in the aquifer sediment and as a separate non-aqueous base.

The contaminant concentrations are the result of the dynamic combination of the aquifers environment, solubility and the groundwaters pH.

Oxidant and contaminant reaction kinetics are faster in the dissolved phase thus sorbed contaminants are not as efficiently treated. Rebounding occurs when contaminant desorb and partition back into the aqueous phase.

Learn more about these physical state changes in our webinar series below.

The contaminant concentrations are the result of the dynamic combination of the aquifers environment, solubility and the groundwaters pH.

Oxidant and contaminant reaction kinetics are faster in the dissolved phase thus sorbed contaminants are not as efficiently treated. Rebounding occurs when contaminant desorb and partition back into the aqueous phase.

Learn more about these physical state changes in our webinar series below.

The mitigation of contaminant rebounding is critical to preventing delays in remediation projects. Learn about our research into this groundbreaking innovation.

|

Learn more about

Rebounding |

Request a free

Site Evaluation |

Let's have a conversation about

Partner with Us |

Read how we approach single treatment

Case Summary |

Case Summary

Petroleum Hydrocarbon (VOCs)

Treatment at a Former Gas Station

Take a deeper dive into

About Rebounding

Request a free

Site Evaluation

Let's have a conversation about

Partnering with Us

Read how we approach single treatment

Case Summary

|

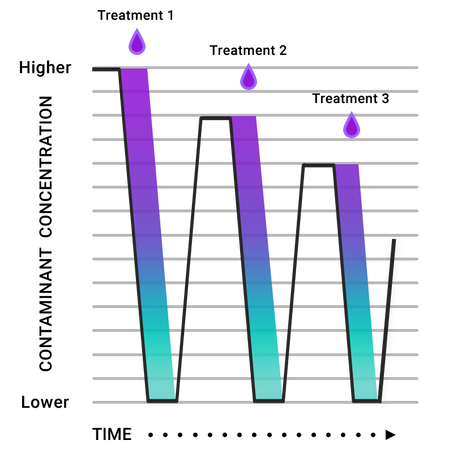

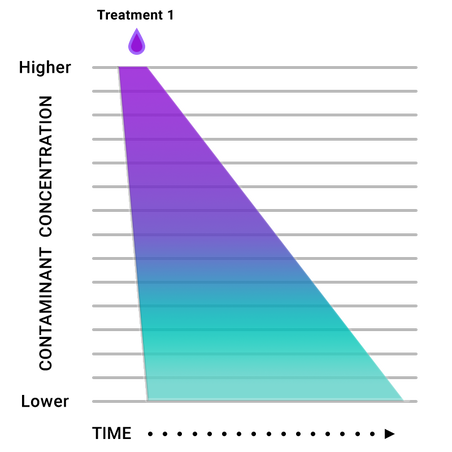

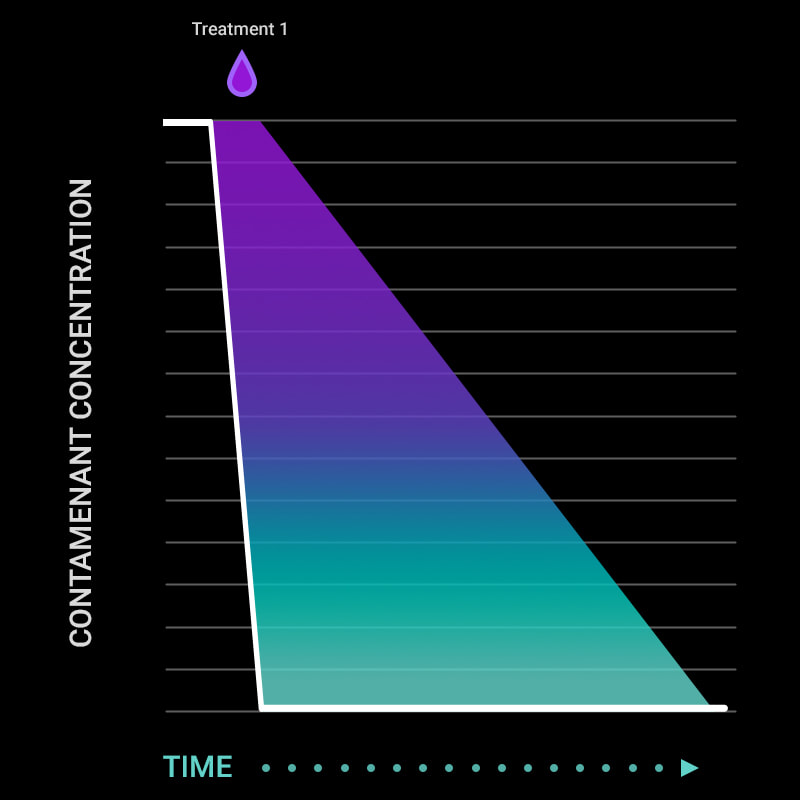

Rebounding is a common issue during in situ remediation. This returning of elevated contaminant levels following a treatment is currently addressed through repeat treatments/injections - driving up cost, delaying time to completion, and prolonging exposure.

|

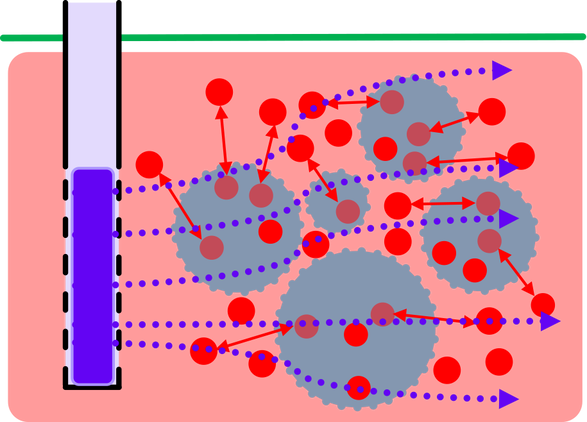

Our controlled release ISCO provides a sustained delivery of oxidants into the subsurface continually degrading contaminants and mitigating rebound.

|

About

Rebounding

Site

Evaluations

Partnering

with us

Case

Summary

|

Rebounding is the return of contaminant levels following treatment, and is currently remedied by repeated treatments – driving up cost, delaying time to completion, and prolonging exposure opportunities.

|

A controlled release ISCO provides a sustained delivery of oxidants into the subsurface continually degrading contaminants and mitigating rebound.

|

|

RemRx® CRP solves this rebounding problem through the delivery of active and sustained reaction kinetics during both aqueous and dissolved hydraulic phases.

|

New ISCO amendments for surface and groundwater remediation.Controlled Release Polymers (CRP) treats environmental contaminants over longer periods of time.

RemRxCRP® addresses rebounding to shorten clean up times and lower overall project costs This patented technology addresses a broad range of commonly found contaminants, typically by-products of industrial manufacturing, cleaning solvents, and agricultural run-off.

|

Rebounding does not have to be a routine part of your game. |