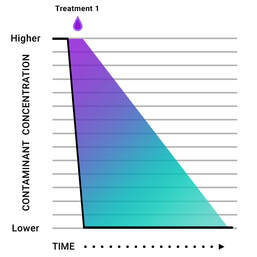

Eliminating the Rebound

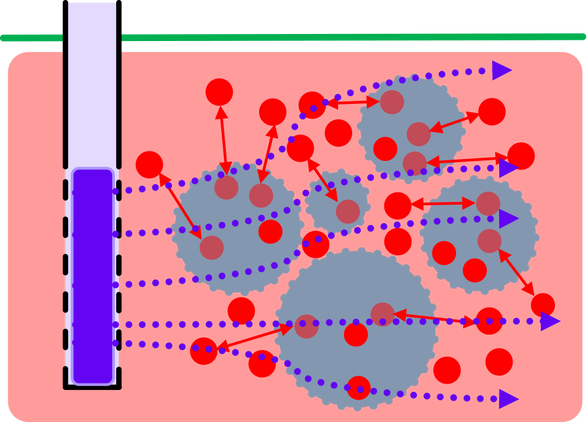

Over time, contaminants change physical states.

What Causes Rebounding?

Contaminant mass can be dissolved in groundwater, sorbed onto solids in the aquifer sediment and as a separate non-aqueous base.

The contaminant concentrations are the result of the dynamic combination of the aquifers environment, solubility and the groundwaters pH.

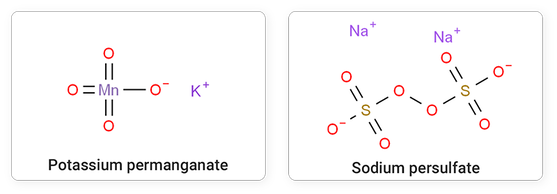

Oxidant and contaminant reaction kinetics are faster in the dissolved phase thus sorbed contaminants are not as efficiently treated. Rebounding occurs when contaminant desorb and partition back into the aqueous phase.

Learn more about these physical state changes in our webinar series below.

The contaminant concentrations are the result of the dynamic combination of the aquifers environment, solubility and the groundwaters pH.

Oxidant and contaminant reaction kinetics are faster in the dissolved phase thus sorbed contaminants are not as efficiently treated. Rebounding occurs when contaminant desorb and partition back into the aqueous phase.

Learn more about these physical state changes in our webinar series below.

The mitigation of contaminant rebounding is critical to preventing delays in remediation projects. Learn about our research into this groundbreaking innovation.