|

“How can we clean up the Earth with a better remediation solution than what's being used today?”

We invented RemRx®. An earth-friendly, controlled release product that mitigates rebounding, lowers project costs and speeds site closures. Faster site closure means more backlogged contaminated sites can begin getting cleaned up. |

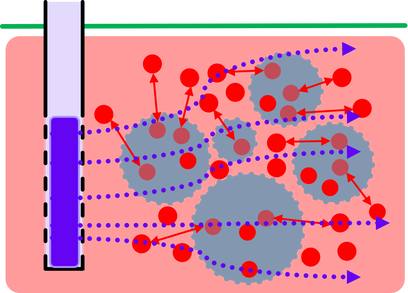

Controlling Sustained Release Over Time

|

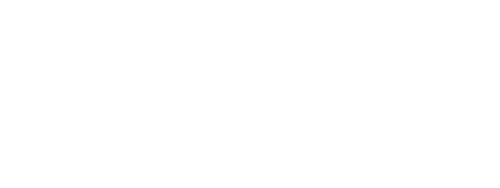

Rebounding is the return of contaminant levels following treatment, and is currently remedied by repeated treatments – driving up cost, delaying time to completion, and prolonging exposure opportunities.

|

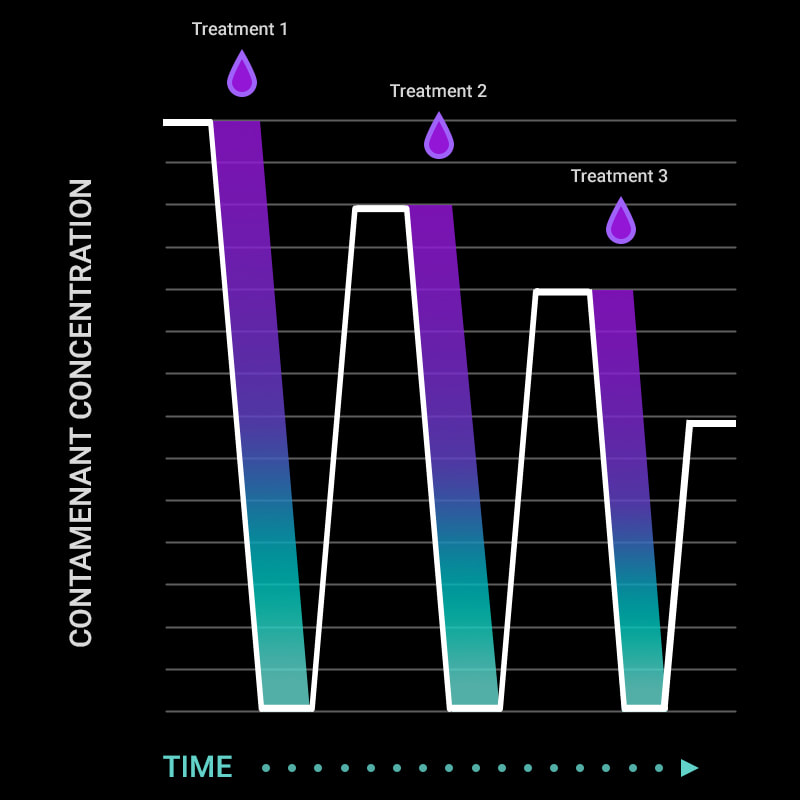

A controlled release ISCO provides a sustained delivery of oxidants into the subsurface continually degrading contaminants and avoiding rebounding.

|

|

RemRx® CRP delivers active and sustained reaction kinetics through the aqueous and dissolved hydraulic phases.

|

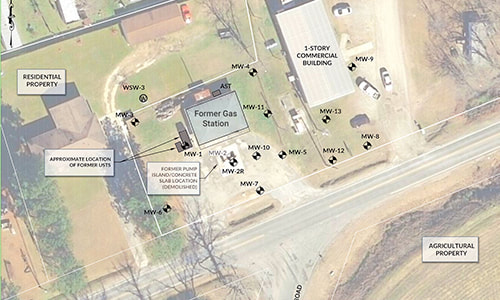

Case Summary: VOCs at Former Gas Station

OverviewThis site, located in Edgecombe County, North Carolina, previously housed two underground storage tanks (UST) used for gasoline storage.

|

ApproachAn excavation perimeter was defined based on a migrating and enlarging plume. Amendments were emplaced interfacing the surficial aquifer.

|

Site SpecificA site specific, prescriptive dosage was formulated consisting of a blended 3:4 ratio of both fast release and slow release CRP.

|

Site Owners and Engineering Professionals

Would you like your site evaluated?

|

Our Technical Consulting Team provides fast, free site evaluations and can provide you with information on current pilots.

|

Eliminating the Rebound

Over time contaminants change physical states.

|

RemRx® CRP delivers active and sustained reaction kinetics through the aqueous and dissolved hydraulic phases.

|

Contaminant mass can be dissolved in groundwater, sorbed onto solids in the aquifer sediment and as a separate non-aqueous base. The contaminant concentrations are the result of the dynamic combination of the aquifers environment, solubility and the groundwaters pH. Oxidant and contaminant reaction kinetics are faster in the dissolved phase thus sorbed contaminants are not as efficiently treated. Rebounding occurs when contaminant desorb and partition back into the aqueous phase. Learn more about these physical state changes in our webinar series below. |

Heading Here!!!

|

What Causes Rebounding?Watch the recorded presentation. The mitigation of contaminant rebounding is critical to preventing delays in remediation projects. Traditional ISCO deployment methods like liquid injection oxidants have known limitations due to rebounding effects.These deployments commonly require costly reinjections and prolong project times.

Similar to the way that controlled release drugs work, RemRx® CRP delivers a sustained dosing to overcome rebounding issues with a single application, increasing efficacy and lowering overall project costs.

|

A Prescriptive DosageRemRx® CRP, is a controlled release product that delivers sustained doses of oxidants directly into contaminated zones.

We use a highly tunable polymer-based matrix that allows release of targeted oxidant doses under specific treatment times and conditions. Complicated hydrogeological aspects in the subsurface mean that each contaminated site is unique. Our tunable technology allows for a prescriptive remediation strategy that is not possible with traditional dissolved oxidant solutions. |

Strategic Teaming Opportunities

Are you part of an established company or agency

in the environmental remediation space?

in the environmental remediation space?

Contact us for information about our pilot programs

opportunities and get in on this groundbreaking innovation.

opportunities and get in on this groundbreaking innovation.